Tell us if this sounds familiar: Your facility decides to double-down on its cleaning and disinfection efforts, and you consider adopting supplemental, automated technology to make your existing processes more consistent and reliable.

But every time you explore an automated solution, your team runs into the same roadblock: You don’t want to add another step to an already involved process. After all, cleaning and disinfecting are time-sensitive tasks, and your staff can’t afford to spend too much of that time on each high-touch surface.

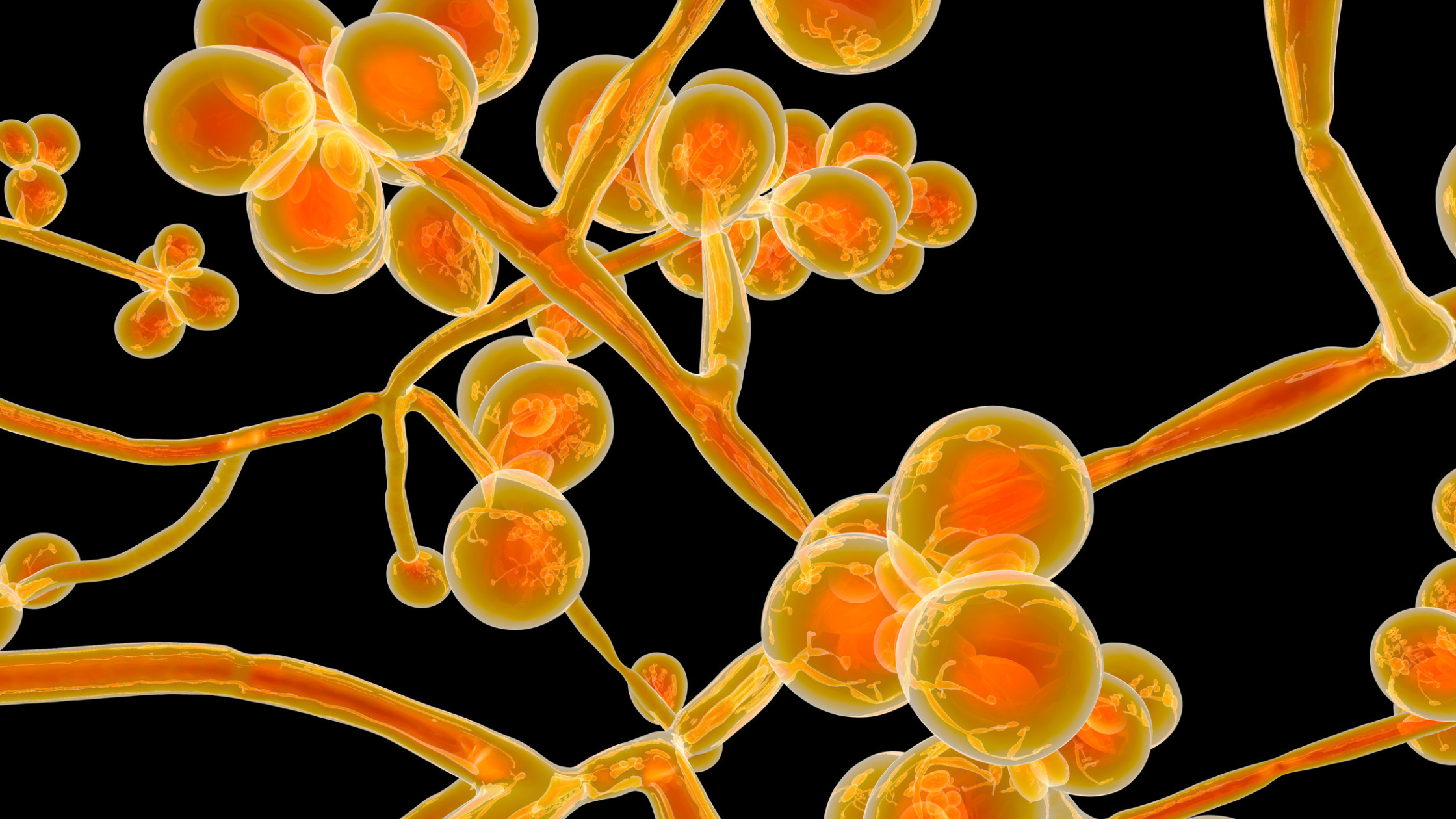

However, as contamination rates of microorganisms like C. auris continue to soar, facilities can no longer rely on manual processes alone to promote a safe environment.

“It’s a needed extra step because the primary process is not adequate,” says Jeremy Starkweather, President and Chief Innovation Officer at UVconcepts. “Until the manual process can be proven to be 100% adequate, you need to have some level of supplemental process to help with the matter.”

Here’s three ways automation can elevate your facility’s disinfection efforts:

1. Controlled variables

Manual wiping is ideal for cleaning and soil removal, but it leaves too many factors to chance for a process as complex as disinfection. According to a 2013 article from the American Journal of Infection Control, some of these factors include:

- Contact time between the disinfectant and surface

- Frequency of wiping

- Ratio of disinfectant to towelette

- Pressure applied to the surface

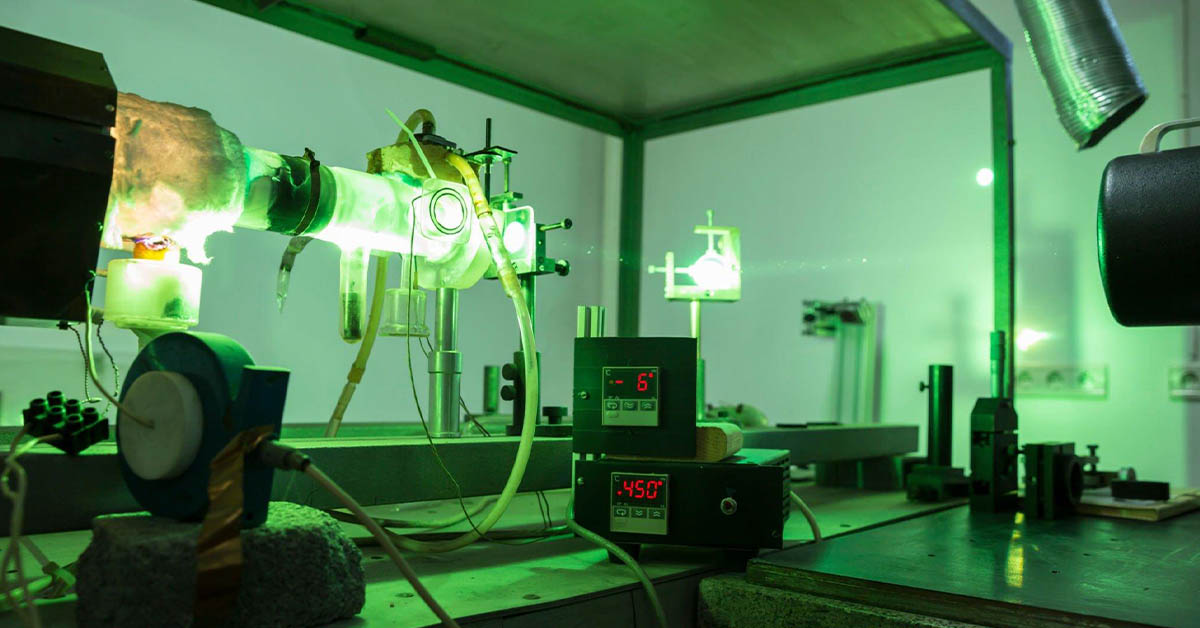

Even if facilities add UV light to their disinfection processes to minimize the human factor, they still need to control for intensity, proximity, and line of sight. Without these safeguards in place, teams can’t ensure that each piece of equipment receives the same dosage level.

Automation accounts for all of these variables by providing a controlled environment for supplemental disinfection. Our UVenclosure, for example, is engineered to control distance, intensity, and line of sight, so no variable is left to chance from one piece of equipment to the next.

2. Creating uniformity across all roles

Environmental hygiene never falls on just one department–but for personnel like nurses or physicians, cleaning and disinfecting come secondary to other responsibilities. Most departments can’t devote the same time to these tasks as EVS can, which produces inconsistent results across the facility.

Plus, when the reporting process consists of just a written log (or the honor system), teams lack the accountability needed to prioritize environmental hygiene.

Digital technology removes these human variabilities like time and experience level. Its intuitive interface allows all personnel, from volunteers to physicians, to have an equal share in promoting environmental cleanliness.

Remember that concern we discussed earlier–that supplemental technology will add yet another step to your processes? Automation won’t make that extra step disappear, but it will ensure that it doesn’t interrupt your existing workflow. Since the automated system conducts the entire supplemental disinfecting process at the click of a button, team members won’t have to neglect their primary duties in order to operate the technology.

Accountability also improves across all departments with digital tracking and reporting features. Our UVdatacloud automatically records each UV cycle upon completion, which means employees don’t have to remember to manually record their activity before returning to their core responsibilities. Hospital leadership can closely monitor protocols and make more informed decisions, while staff members can continue focusing on their jobs–confident that their supplemental disinfection process is taking care of the rest.

3. Promoting a safer work environment

Digital technology doesn’t just benefit patients. Facilities that choose to automate their supplemental disinfection processes can also promote safety among their staff.

Manual supplemental systems put teams at risk of harmful exposure, whereas automated systems like the UVenclosure administer the UV light automatically and in a closed environment. This means staff members don’t have to interact directly with radiation, which protects them from harmful side effects and contributes to a happier work environment.

Illuminate Your Environment with Automation

Good manual processes are essential to cleaning, but their uncontrolled variables prove challenging for proper disinfection. Supplemental, automated systems like the UVconcepts Technology Suite fill in those gaps with controlled UV-light technology and cloud-based analytics that ensure consistency, accountability, and oversight.

Get in touch with our team to find out how the UVconcepts Technology Suite can enhance your facility’s disinfection processes.